Introduction

The “Birth Story of the Outdoor Waterproof 18×18W LED PAR Light” takes you through the complete journey of how a truly reliable outdoor lighting fixture is created. A professional-grade waterproof LED PAR light must withstand ever-changing outdoor environments—rain, humidity, heat, frost, dust, and mechanical vibration. Its reliability comes from a combination of precise structural engineering, rigorous production processes, and uncompromising quality control standards.

Brands like Blue Sea Lighting have developed deep expertise in waterproof LED fixture manufacturing, enabling their products to deliver long-term performance across architectural lighting, landscape illumination, theme parks, and outdoor entertainment.

This article explains the foundational waterproofing principles, the production workflow, key inspection procedures, and purchasing tips that can help you evaluate the quality of an outdoor LED PAR light.

1. How Does a Lighting Fixture Achieve Waterproof Protection?

Outdoor lighting fixtures must operate in unpredictable conditions. Achieving true waterproof performance requires more than simply adding glue or a basic seal—it is a multilayer engineering process. The core waterproofing methods include structural sealing, glue-potting, and optimized mechanical design.

1.1 Structural Waterproof Sealing

Structural sealing is the most widely adopted and reliable waterproof strategy in the professional lighting industry. It uses mechanical interfaces and elastic materials to form a long-lasting physical barrier against water intrusion.

Key structural sealing components include:

Silicone O-rings and sealing gaskets

Positioned at critical joints such as the front cover, housing, back plate, and cable entry.

Some high-end designs adopt dual-layer O-rings, where the second seal provides protection even if the first begins to age.Waterproof cable glands

These prevent water from entering through power cables, which are common leak points in outdoor equipment.Precision-machined housings

High-quality aluminum housings with tight tolerance and smooth contact surfaces minimize gaps that water could penetrate through.

This method forms the backbone of professional IP-rated waterproof engineering.

1.2 Glue-Potting Waterproofing

Glue-potting is applied to sensitive components for additional waterproof and moisture-resistant performance.

Typical glue-potting applications include:

Filling epoxy resin or silicone around the LED board, preventing moisture from reaching LED solder joints

Applying thermal silicone around the driver PCB to protect electrical circuits while enhancing heat conduction

Using sealant between the lens and housing to eliminate tiny gaps

This technique is commonly used in LED strips and modules but also provides valuable reinforcement for professional outdoor fixtures.

1.3 Optimized Structural Design

Before adding waterproof components, engineers optimize the fixture body to reduce water infiltration risks.

Effective structural strategies include:

Eliminating unnecessary grooves or deep recesses

Preventing screw holes from penetrating sealed chambers

Designing natural drainage paths

Reducing external machining allowances to avoid micro-pores in castings

Reinforcing joint areas affected by thermal expansion

An optimized structure not only improves waterproof stability but enhances long-term durability.

2. Main Production Stages of an Outdoor LED PAR Light

Producing a professional outdoor fixture involves multiple tightly controlled manufacturing stages. Each step plays a vital role in ensuring long-term outdoor stability.

2.1 Incoming Material Inspection

Quality starts with raw materials. Every component must be inspected before entering the production line.

Inspection items include:

LED Source Module

Check for appearance defects, proper soldering, lamination quality between LEDs and aluminum substrate, and initial electro-optical testing.Lighting Housing

Ensure no dents, scratches, or coating defects. Verify structural accuracy and sealing surfaces.Driver / Constant Current Power Supply

Confirm stability, correct parameters, and safe insulation for outdoor environments.Sealing Components (O-rings, gaskets, waterproof glands)

Inspect for elasticity, density, size accuracy, and surface finish.

Thorough IQC (Incoming Quality Control) is the foundation of consistent product quality.

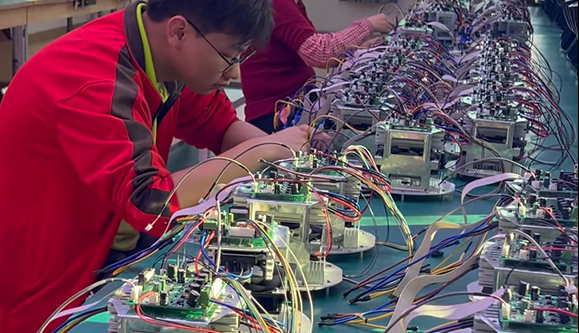

2.2 Assembly Process

The assembly phase requires precision and technical expertise to ensure proper waterproof performance, electrical safety, and optical quality.

Key assembly procedures include:

① LED Module Installation

Apply a uniform layer of thermal grease to ensure effective heat transfer

Fix the aluminum PCB onto the housing tightly

Verify full contact between module and heat sink surface

Good thermal management directly affects LED lifespan.

② Soldering and Wiring

Use high-temperature silicone cables

Ensure firm solder joints with no cold solder or bridge solder

Protect joints using heat-shrink tubing

Route cables cleanly to avoid friction and interference

Proper wiring is essential for long-term reliability.

③ Installation of Sealing Components and Lens

Install O-rings, gaskets, waterproof lenses, or glass

Ensure each sealing ring fits properly into its designated groove

Inspect optical components for dust or defects

An improper seal may compromise waterproof performance.

④ Rear Cover and Cable Gland Installation

Install end caps or rear covers

Verify gasket alignment

Insert cables through waterproof connectors and tighten securely

This is one of the final waterproof layers.

2.3 Aging Test (Up to 48 Hours)

Before packaging, assembled fixtures undergo long-duration burn-in testing.

Aging test checks:

Temperature stability

Electrical current and voltage behavior

Light output performance

LED failure (dead pixels)

Driver reliability

Professional manufacturers such as Blue Sea Lighting typically perform aging tests on each unit or batch to ensure long-term outdoor performance.

3. Key Inspection Stages

Rigorous inspection ensures every lighting fixture meets professional standards.

3.1 Power-On Electrical Testing

Each unit undergoes:

Full illumination test

Short-circuit check

Channel output verification

Flicker and brightness consistency evaluation

Electrical safety and optical performance must meet design standards.

3.2 Appearance and Waterproof Testing

Inspectors examine each product’s:

Surface finish

Assembly accuracy

Sealing ring compression

Structural integrity

Waterproof testing follows the product’s rated IP level (IP65, IP66, or higher), including:

Simulated rain exposure

High humidity

Freeze–thaw cycle testing

Heat and condensation resistance

Only products that pass all waterproof tests can be shipped.

4. How to Choose a High-Quality Outdoor LED PAR Light

Understanding the production process helps you evaluate product quality more effectively.

4.1 Check Waterproof Rating and Engineering

Key waterproof indicators include:

IP rating: IP65, IP66, or IP67

Structure sealing vs. glue-potting

Dual O-ring design for enhanced reliability

A truly waterproof fixture must use multiple sealing layers.

4.2 Evaluate Heat Dissipation

LED lifespan and performance depend heavily on heat control.

Look for:

Aluminum or magnesium alloy housings

Professional heat-sink structures

Use of thermal paste

Good airflow inside the LED chamber

4.3 Review Production and Quality Control Processes

Ask whether the manufacturer:

Performs 100% power-on inspection

Conducts aging tests

Conducts waterproof testing per IP standard

Brands like Blue Sea Lighting maintain excellent quality control systems.

4.4 Evaluate Optical Components and Features

For advanced applications, a fixture may need:

Adjustable beam angles

High-quality lenses

Precision optical engines

Optional zoom mechanisms

Optics determine the fixture’s visual performance.

Conclusion

A professional outdoor waterproof 18×18W LED PAR light is the result of precise structure, high-level engineering, disciplined production, and strict quality management. Only manufacturers with strong R&D and production capacity—such as Blue Sea Lighting—can consistently build high-quality outdoor fixtures capable of withstanding harsh environments while maintaining stable lighting output.

Understanding these principles enables users to choose products that deliver long-term reliability and outstanding performance.

Blue Sea Lighting is an enterprise with rich experience in the integration of industry and trade in stage lighting and stage special effects related equipment. Its products include moving head lights, par lights, wall washer lights, logo gobo projector lights, power distributor, stage effects such as electronic fireworks machines, snow machines, smoke bubble machines, and related accessories such as light clamps.

Quick Links

For more questions subscribe to our email